GTSP Building

Problem -

Challenges -

Solution -

The extremely corrosive atmosphere severely damaged pre-cast double-Ts, some with the pre-tensioned cable exposed and broken. The majority of the damage was in the top 1/3 of the the 65' high building.

The building was to remain operational while the repairs were being done. The air inside the building required the use of full face respirators with filters changed every four hours and the use of protective suits.

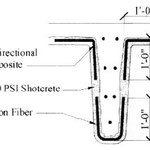

Erect scaffold 50 feet high under the entire work area. Build an enclosure around the conveyor belt to ensure continuous operation. Chip all loose, treat all exposed metal with a corrosion inhibitor and bonding agent, apply concrete using 7,000 psi shotcrete. Wrap the bottom of the beams with carbon fiber for additional strength.

Complete the repair using a roller applied rubber coating to seal the concrete from the corrosive fumes.